Squid-ring plastic for tricky fixes

Engineers in the US have developed a self-healing, super-strong polymer made from the rings of a squid.

Engineers in the US have developed a self-healing, super-strong polymer made from the rings of a squid.

The substance repairs itself with the addition of a drop of water.

The multiphase polymer derived from the genetic code of squid ring teeth could be used to extend the life of medical implants, fibre-optic cables and other objects that are hard to repair in place.

“What's unique about this plastic is the ability to stick itself back together with a drop of water,” said Melik Demirel, professor of engineering science and mechanics at Penn State University.

“There are other materials that are self healing, but not with water.”

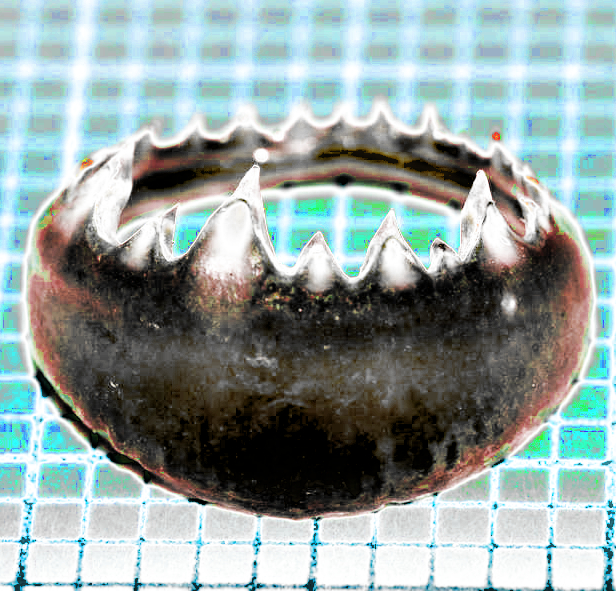

Demirel and led a team of bioengineers looking at the ring teeth of squid collected around the world - in the Mediterranean, Atlantic, Hawaii, Argentina and the Sea of Japan - and found that proteins with self-healing properties were everywhere.

But “the yield of this proteinaceous material from natural sources is low (about 1 gram of squid ring teeth protein from 5 kilograms of squid) and the composition of native material varies between squid species”, their report states.

To save squid populations, and to have a uniform material, the researchers used biotechnology to create the proteins in bacteria. The polymer can then either be moulded using heat or cast by solvent evaporation.

The two-part material is a ‘copolymer’, consisting of an amorphous segment that is soft mixed with a more structured molecular architecture.

The two-part material is a ‘copolymer’, consisting of an amorphous segment that is soft mixed with a more structured molecular architecture.

The structured portion consists of strands of amino acids connected by hydrogen bonds to form a twisted and/or pleated sheet. This part also provides strength for the polymer, but the amorphous segment provides the self-healing.

The researchers created a small dog-bone shaped sample of the polymer (have a look in the video below) and then cut it in half. Using warm water at about 45 degrees Celcius - slightly warmer than body temperature - and a small amount of pressure with a metal tool, the two halves were reunited to reform the dog-bone shape.

Strength tests showed that the material after healing was as strong as when originally created.

“If one of the fiber-optic cables under the ocean breaks, the only way to fix it is to replace it,” said Demirel.

“With this material, it would be possible to heal the cable and go on with operation, saving time and money.

“Maybe someday we could apply this approach to healing of wounds or other applications.

“It would be interesting in the long run to see if we could promote wound healing this way so that is where I'm going to focus now.”

More details are available here, in the full report.

Print

Print