CO2 in vitamin drive

German scientists are feeding microbes CO2 and creating protein-rich yeast that outdoes beef.

German scientists are feeding microbes CO2 and creating protein-rich yeast that outdoes beef.

Researchers have developed a new method for producing protein and vitamin B9 using microbes, hydrogen, oxygen, and CO2, potentially offering a sustainable alternative to conventional food production.

The process relies on renewable energy and aims to tackle global challenges, including food security, environmental conservation, and public health.

The research team, led by Largus Angenent from the University of Tübingen, designed a two-stage system to produce nutrient-rich yeast.

The first stage involves the bacterium Thermoanaerobacter kivui, which converts hydrogen and CO2 into acetate, a compound found in vinegar.

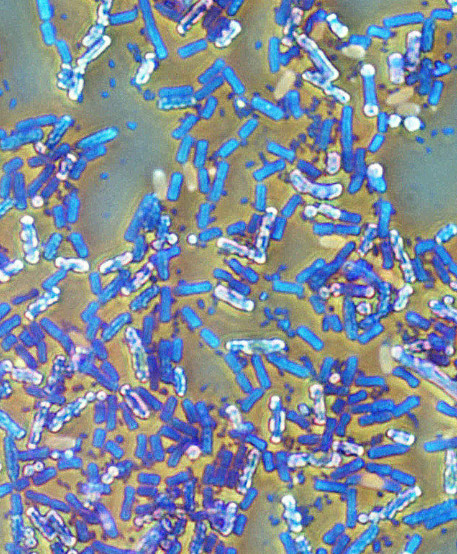

In the second stage, baker's yeast (Saccharomyces cerevisiae) consumes the acetate and oxygen to produce both protein and vitamin B9, also known as folate, an essential nutrient for cell growth and metabolism.

“This is a fermentation process similar to how you make beer, but instead of giving the microbes sugar, we gave them gas and acetate,” Angenent says.

He added that while yeast is known to produce vitamin B9 when fed sugar, this study was the first to show it could do the same with acetate.

The potential of this technology lies in its ability to produce food without land use, a critical consideration as the global population approaches 10 billion and climate change threatens agricultural production.

“One alternative is growing proteins in bioreactors through biotechnology rather than growing crops to feed animals,” Angenent said.

The yeast produced through this process has protein levels that surpass traditional sources such as beef, pork, fish, and lentils.

Additionally, less than half a teaspoon of the dried yeast meets daily vitamin B9 requirements, making it a promising nutritional source.

The technology runs on clean energy, with hydrogen and oxygen derived from water electrolysis powered by renewable sources like wind energy.

This approach not only reduces carbon emissions but also frees up land for conservation purposes.

Furthermore, it offers a solution for addressing malnutrition in developing nations by providing a reliable source of protein and essential vitamins.

However, the team acknowledges that further work is needed before this microbial protein can be commercially viable.

They plan to optimise and scale up production, conduct safety assessments, and perform technical and economic evaluations.

Despite these challenges, Angenent is optimistic.

“The fact that we can make vitamins and protein at the same time at a pretty high production rate without using any land is exciting,” he said.

The team’s research has been published in Trends in Biotechnology.

Print

Print